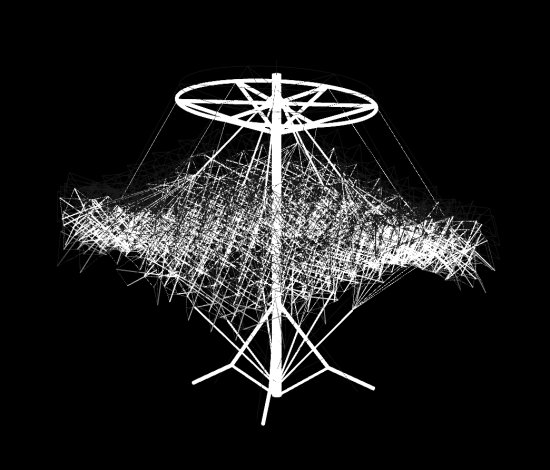

As part of the ArchManu ARC Next-Gen Architecture Research Program and its ongoing series of hackathon events, our colleagues Alina Schuster and Matthew Tam joined forces with Cox Architecture and researchers from UNSW, Adelaide University, and Swinburne University of Technology to explore how AI can drive low-carbon innovation in structural design.

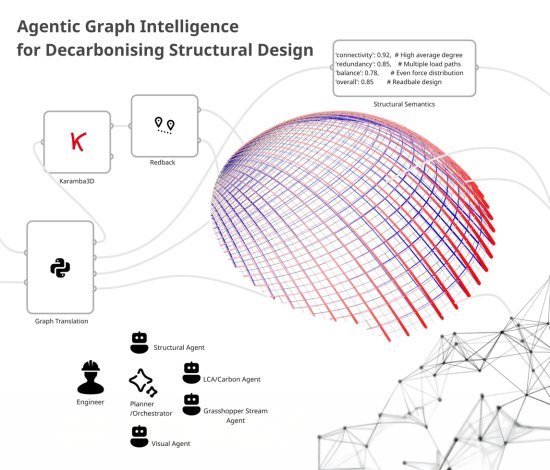

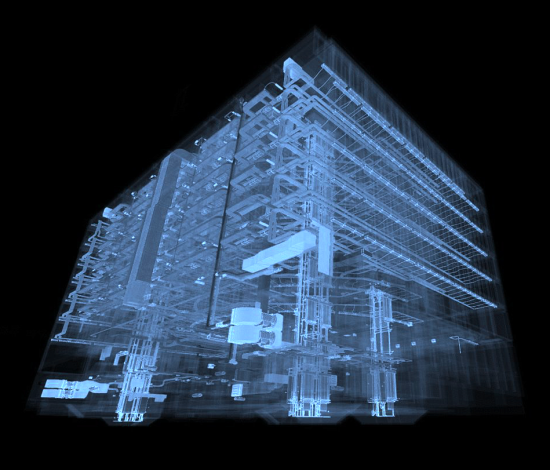

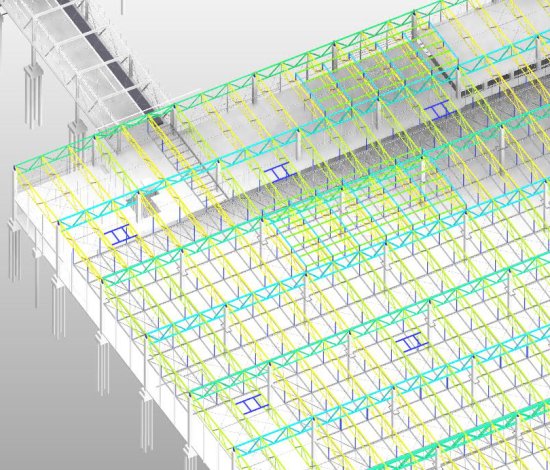

Their project, 'Agentic Graph Intelligence for Decarbonising Structural Design', introduces a graph-based framework that redefines optimisation, moving beyond material reduction toward a relational understanding of geometry, connectivity, and semantics.

Through agentic AI orchestration, specialised agents interpret the Structural Graph Database to propose design adjustments that balance structural performance and carbon reduction moving toward AI-readable, data-driven structures where design, fabrication, and sustainability are intelligently connected.

Visual: Arch_Manu

As part of the Arch_Manu Research Program and its ongoing series of hackathon events, our colleagues Alina Schuster and Matthew Tam initiated the Structural Carbon Bot hack project. During the hackathon, the team created a structure-aware AI model by fine-tuning it with training data from Karamba3D. The project was developed by a dedicated team of PhD and Master’s students working closely with our colleague Alina.

The team's concept and results in such a short time were truly impressive. Details about it will follow soon. We look forward to seeing how the project continues to grow during the next Hackathon this autumn, when the hack is further developed, including aspects of sustainability.

Arch Manu successfully hosted its first Hackathon in 2025, from February 12 to 15. This event brought together 38 researchers and industry professionals from around the world to explore innovative digital methods for architectural and structural design.

How can we meaningfully compare buildings to better understand their relative performance? This question was central to the ‘Comparability of Buildings’ project, proposed by our colleagues Ljuba and Alexander.

Two Arch_Manu PhD candidates worked with a team of Grimshaw Design Technology specialists to develop a solution leveraging graph-based representation and key performance indicators (KPIs). They tested the approach on a comparison of structural systems.

For the Design Modelling Symposium 2024 in Kassel, our colleagues Matthew Tam (Karamba3D), Ljuba Tascheva, and Alexander Hofbeck teamed up with Jonathon Broughton and Björn Steinhagen of Speckle to develop a hackathon-style workshop for the conference participants.

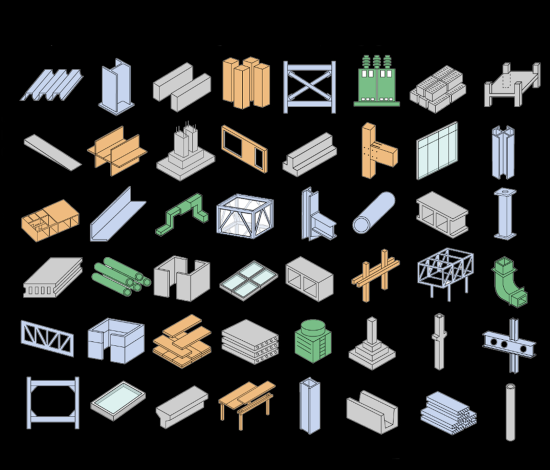

The workshop’s concept was based on the scarcity of construction materials, acknowledging that the earth's resources are finite. Participants were tasked with collecting virtual construction elements from existing buildings stored in Speckle, which serves as a material bank. They were to reuse these elements to design new pavilions for the contemporary art exhibition ‘documenta’, held in Kassel every five years.

Despite the challenging task, every team developed the entire workflow for reuse and data collection from scratch in Grasshopper. All participants rose to the challenge, showcasing their creativity and bravery as they developed three unique and innovative concepts!

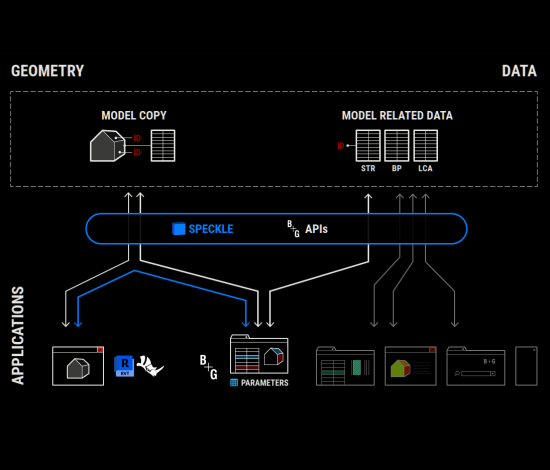

Our colleague Steffen, who is part of our Design Technology Group and one of the developers of our digital design pipeline, sat down with Speckle to discuss the challenges of developing user-friendly tools and transferring workflows from analogue to digital.

In the story, he showcased his latest development, the Speckle Parameter App. This tool allows for data entry into 3D models and has the potential to become a project explorer and data manager beyond the obvious BIM appliances. The link to the article is below if you want to know more!

As part of the Arch_Manu Research Program, our colleagues Ljuba, Marc, and Alexander formed a hackathon team with a group of Grimshaw design Technology specialists.

The project’s initial challenge was establishing a framework of rules for the kits of parts, essentially creating a recipe for modular fabrication or a kit of rules. In the second step, colleagues of Grimshaw used the open-source housing data from WikiHouse, leveraged the Topology package for Grasshopper, and tried to understand the topologic connection/relationship between the elements using Graph-based Machine Learning. The hackathon was a big learning experience for both teams and a good foundation for future hackathons at Arch_Manu.

The inaugural Arch_Manu hackathon took place on June 18–19, 2024, bringing together 20 passionate participants from Australia, the UK, France, and the USA.

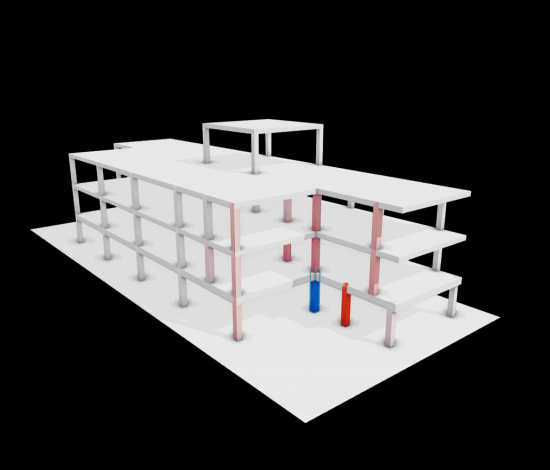

Our colleagues Steffen Samberger, Wyeth Dean Binder, and Matthew Tam participated in the Beyond the Speckleverse hackathon, which took place June 7 – 9, 2024. Their hack, ‘What.If.Architect’, won the ‘Most Impressive Use of Business Intelligence’ award!

‘What.If.Architect’ enhances communication and decision-making in structural and architectural design by re-visualising data through geometry. This approach addresses challenges with traditional methods, providing better understanding and flexibility in design. Built using Rhino and Karamba3D, ‘What.If.Architect’ analyses the impact of removing structural elements such as columns and visualises these effects through Speckle, helping stakeholders make more informed decisions. Despite initial challenges in creating a dynamic loop for real-time analysis, the team developed a robust brute-force analysis method, showcasing their dedication and ingenuity. Learn more about the ‘What.If.Architect’ hack through the links below!

Alexander Hofbeck (B+G) and Alan Rynne Vidal (software engineer at Speckle) spoke at the AEC Hackathon, which took place 2–4 February 2024 in Zürich. Alexander presented our vision of digital collaboration with the open-source startup and gave an overview of B+G internal software developments like the Speckle-based B+G Parameter App and the B+G Knowledge Hub.

The ARC Centre for Next-Gen Architectural Manufacturing is an interdisciplinary, industry-focused research and training initiative funded by the Australian Research Council. As the program is industry-focused, we have been proud members of this program since its commencement, along with Architectus, Cox Architects, Tzannes, and Grimshaw.

This program aims to accelerate digital transformation processes within the Architecture, Engineering, and Construction sectors to meet critical sustainability goals. We are contributing to this program by supporting the PhD students, providing and attending hackathons, providing specific research tasks, and using the program as a bilateral incubator for digital innovations in the fields of digital and emerging technologies.

Our colleagues Ljuba Tascheva and Alexander Hofbeck were invited to talk at Specklecon on 14 November 2023. Their talk ‘Digital Design Communication’ revisited the façade workflow for the high-rise Elbtower, showing how it would have been executed using the Speckle platform. Additionally, they presented an overview of our Digitalisation Strategy.

Specklecon is an online conference of the AEC open-source startup Speckle. Speckle is focused on revolutionising collaboration in the AEC industry. They specialise in developing open-source software that facilitates seamless sharing and communication of 3D design data among various stakeholders, enhancing efficiency and transparency in project workflows.

Sandie Kate Fenton participated in this year's 2023 IASS session, themed ‘Integration of Design and Fabrication’, where she presented her research on the life cycle assessment and design of structures. Her presentation centred on her work involving a machine-learning approach to predict the embodied carbon of lightweight structures.

This symposium emphasises the growing significance of digital technologies in various design and manufacturing domains. It allows attendees to engage in lectures and masterclasses conducted by experts from institutions and companies around the globe.

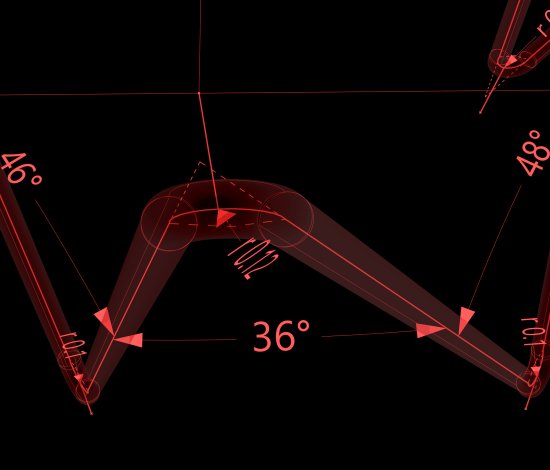

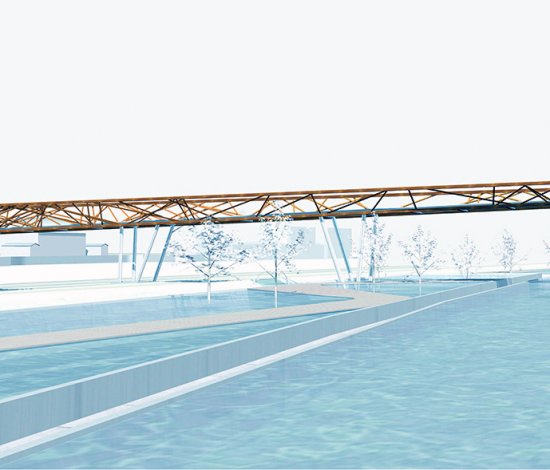

To manage the spatial and geometrical restrictions for the Fast-Charging Station Leipzig efficiently, the entire process was executed through a closed digital process chain. Our team worked closely with the architects to develop the geometry for the filigree support structure with the help of an evolutionary optimisation algorithm.

Philipp Eisenbach, Klaus Bollinger and Moritz Heimrath from B+G wrote an in-depth article in ‘Stahlbau’ (Ernst & Sohn, Berlin) together with Jon Prengel from raumwerk Gesellschaft für Architektur und Stadtplanung mbH about the project development.

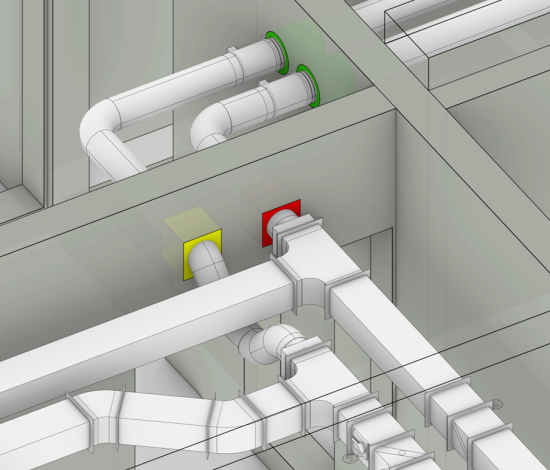

As part of the Revit User Group DACH, we co-authored the Autodesk MEP Coordination Guideline, providing a comprehensive overview and support for designers interested in the topic and deeper insights for field experts. The document represents the holistic view of the coordination process for MEP openings throughout the design phases.

Authors: Tanja Gutena (Architect, gmp architects), Fabian Matschinsky (MEP-Engineer, HL-Technik) and Alexander Hofbeck (B+G)

Over the years, our Design Technology Group has developed various tools, partially released to the public, e.g., on the Autodesk App Store. We started our GitHub organisation to evolve our developments, maintaining and enabling collaboration on our public and private coding projects.

Feel free to follow us, fork our public coding projects or look at what we are up to!

Alexander Hofbeck (B+G), Tanja Gutena (architect, GMP Architekten / Sprinkenhof GmbH), and Fabian Matschinsky (MEP, HL-Technik) were invited to speak at the digital forum ‘Digitaltour: Schlitz- und Durchbruchsplanung ’, which took place online on 27 July 2022.

The trio offered their insights on the model-based builders’ work opening coordination process and how BIM methodology can significantly optimise this process regarding time, effort, and error susceptibility. The presentation offers a comprehensive overview of the process as it engages in a dialogue between the primary disciplines of building design. It is based on their Autodesk Modelling Guideline, which can be found through the link below.

The interactive and performative robotic installation ‘Anthropomorphic Machine’ comprises pneumatic rubber ‘muscles’, steel tendons, a deformable tensegrity skeletal structure, a circulatory system of compressed air, and a vision and computational system, allowing it to sense and react in the presence of humans.

The machine is linked to multiple cameras, which allows it to respond to the person’s movements by moving parts or all its 498 stainless-steel struts in the skeletal structure with the help of its circulatory system of compressed air.

For this eight-meter-high sculpture, which was exhibited at the Science Gallery, performance artist Stelarc collaborated with Melbourne School of Design, LLDS Architecture, and PhD students at the School of Computer Science and Information Systems, Pelican Studios, Festo, and Bollinger+Grohman.

The creation of the pavilion, Re/Place, by Studio Chris Fox evolves around natural materials and how a design can be adapted to their respective life cycles. This temporary and modular pavilion is made from reclaimed timber and mycelium to engage visitors in a discussion about the circular economy, possibilities for re-using materials and how we think about architecture.

Re/Place Pavilion is an installation collectively designed and developed by Studio Chris Fox and Bollinger+Grohmann in partnership with the University of Sydney and Swinburne University of Technology.

Photo: Jeremy Weirauch

Our master’s student Niklas Haschke won the second prize in the 2022 ‘Building outside the box’ award for his master’s thesis project, ‘Structural Web Tool’.

The master’s thesis aimed to develop a new concept for integrating life cycle assessment in the early design stages and comparing several design variants. To achieve this, computational design concepts such as Building Information Modelling, parametric methods, and scripting were applied to the developed tool. Using open-source tools and web technologies, a platform-agnostic approach was employed to expand the application’s range and address compatibility issues.

‘Building Outside the Box’ is an innovation prize regularly awarded by the Bavarian Chamber of Engineers in Munich.

Ganga Surendran Sanila, our master’s thesis student, won first place in the ‘Hochschulpreis des Bayerisches Baugewerbe 2022’.

The master’s thesis focused on an object-based and data-centric coordination process for approving or declining the builders’ work openings of construction projects. The technical foundation of the digital process was a graph database in the backend, which tracks the history (change) of each object (provision for void) by mutating the graph data structure for each change. As a proof of concept, a Revit plugin was developed to allow the user to check and verify the openings.

This annual award recognises exceptional theses in civil engineering. The award ceremony was held at the Oskar von Miller Forum in Munich, which also hosted the Bollinger+Grohmann exhibition ‘Faszination Bauprozess’ in 2015.

‘Remnants of a Future Architecture’ is a series of architectural artefacts investigating new digital fabrication methods and their impact on future architecture.

Studio Roland Snooks developed Remnant 1 in collaboration with RMIT Architecture | Tectonic Formation Lab and FormX Technology using Wire Arc Additive Manufacturing (WAAM) for the 3D printing process. The printing is executed by stacking layers of metal on top of each other with the help of a welding robot.

The design for new balcony structures of a Parisian residential building explores the concept of mapping results from a topological optimisation onto a lattice spaceframe structure. Inspired by Hector Guimard's ‘Art-Nouveau’ metro stations, the computational design combines principles from structural optimisation with an organic design language that expresses the flow of forces.

The idea for the fabrication involves utilising metal 3D printing technologies to create a 1:1 construction of the design.

Image: Bona-Lemercier Architectes

Leidorf GmbH has recently finished assembling the primary structural elements of the Spähikel research pavilion.

The mobile structure can be encountered in different locations within the forests of Upper Austria soon.

Photo: mostlikely architecture

Adam Orlinski and Moritz Heimrath co-authored the chapter ‘Fluid Structures – Formed by Force’, recently published in the new book ‘Fluid Bodies – Methods for Casting New Esthetics’.

The book features contributions by:

Paul Clousier, Luca Conte, Anton Defant, Marco Dessi, Studio Stefan Diez, Anna Heimrath, Moritz Heimrath, Cathrine Hu, Mato Johannik, Ursula Klein, August Kocherscheidt, Christine König, Quirin Krumbholz, Studio Greg Lynn, Adam Orlinski, Bence Pap, Giulio Polita, Studio Klaas de Rycke, Michael Tingen, and Rupert Zallmann

‘Fluid Bodies – Methods for Casting New Esthetics’

Rupert Zallmann, Editor and the Institute of Architecture at the University of Applied Arts Vienna (Eds.)

Edition Angewandte, Birkhäuser Basel, 2022

ISBN: 9783035625868

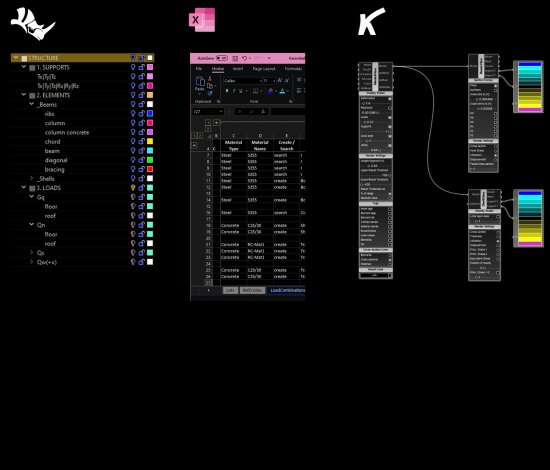

The recently developed ‘Karamba3D Template’ establishes a connection between 3D geometry sourced from Rhinoceros3D layers and spreadsheet data organised in Excel.

This allows the organisation of all the model data with a powerful data structure and simplified and controlled interaction with all input parameters.

The template provides assistance with load combinations by automatically assigning information to different parts of the model. Furthermore, it facilitates geometry management, performs various modelling operations, and checks to ensure the model geometry is adequately prepared for calculation. The template allows users to build Karamba3D models with high model complexities while simplifying the interface and optimising the workflow.

The ‘Karamba3D Template’ was developed by our Design Technology group.

The chapter ‘Encoded Structures - Constraint-Based Design of Modular Beams’, co-authored by Adam Orlinski, Clemens Preisinger and Moritz Heimrath, was recently published as part of the new book: ‘Conceptual Joining: Wood Structures from Detail to Utopia’.

‘Conceptual Joining: Wood Structures from Detail to Utopia’

Lukas Allner, Christoph Kaltenbrunner, Daniela Kröhnert, Philipp Reinsberg,

University of Applied Arts Vienna & Birkhaüser, 2021

ISBN: 9783035624359

In ‘Digitaltour: ESO Supernova in Garching,’ our colleagues Moritz Heimrath and Alexander Hofbeck presented insights into the design and construction process of the ESO Supernova, an observatory, and museum in Garching.

The ESO Supernova was designed with a unique fully streamlined digital parametric pipeline by the architects of Bernhardt+Partner and the engineers at Bollinger und Grohmann. The development considered aspects of parametric model generation, analysis, lists, and drawings to bring the design of the Supernova into reality.

The final result of the art-based research project ‘Fluid Bodies’ will be exhibited at the Wotruba-Atelier.

Vernisage, 1 June 2021, 6 p.m.

Rustenschacher Allee 2–4, 1020 Vienna, Austria

FWF Research Program, University of Applied Arts Vienna

with Madame Architects and Bollinger+Grohmann

The robotic fabrication process for the new mobile pavilion of the Austrian Federal Forests Association has started.

The small project is a movable forest observatory that hosts multiple guests.

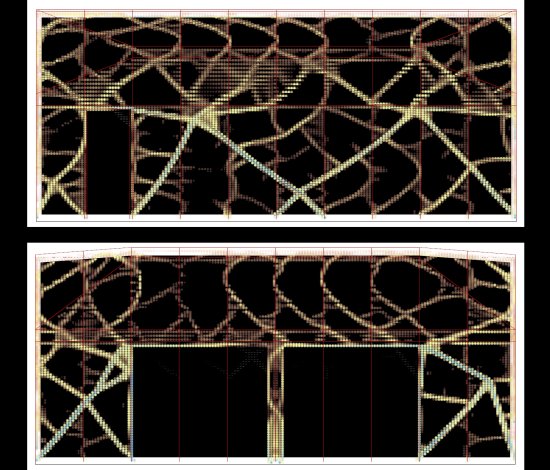

The structure consists of Kerto LVL Q-panels that were CNC-cut by a robotic arm. The cutting pattern was generated with the help of a topology optimisation routine that responds to a series of loads while respecting a specific architectural design domain, which was developed within the art-based research project ‘Fluid Bodies - Casting Without Formwork’.

Video: Leidorf

Sandie Kate Fenton is currently conducting her PhD research: ‘A machine learning approach for predicting embodied carbon of structures at early design stages’ within a collaborative framework between Bollinger+Grohmann, énsa-Versailles, and Vrije Universiteit Brussel.

The research focuses on the embodied carbon footprint of building structures and aims to provide a comprehensive understanding of design-driven factors influencing the footprint.

Its objective is to facilitate access to early-design assessments that use Machine Learning regression models to predict embodied carbon footprints using descriptive data available at early-design stages rather than quantitative data.

The expected output is an interactive tool for data-driven low-carbon structural design.

As part of the Autodesk University Industry Talk in 2020, our colleagues Laura Hinkel and Alexander Hofbeck presented current developments and application-oriented project examples from our everyday work as a planning office. ‘Workflows: Collaborative Processes and Parametrics in Structural Design’ mainly focused on topics concerning cloud-based BIM processes and parametric BIM with hands-on examples using Karamba3D within the Revit environment.

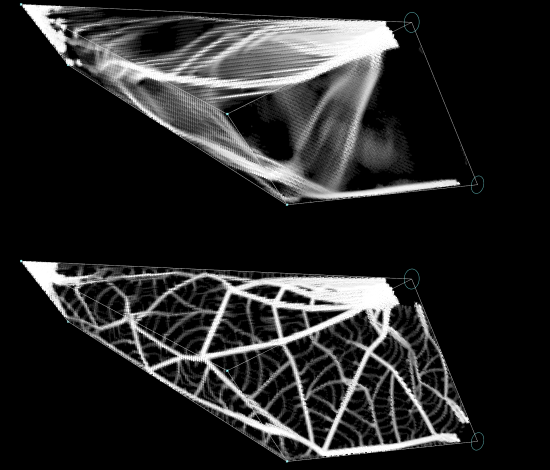

Spähikel is a research project that explores the application of ‘Topology Optimisation’ in creating efficient, lightweight structures within predefined poly-surface design domains. This involves utilising input geometry, support areas, and various load sets to iteratively converge on a condensed structural shape.

Through an iterative calculation process, an algorithm cuts material and incrementally refines the design, uncovering patterns demonstrating enhanced structural performance while substantially reducing material usage.

Autodesk’s first digital edition of ‘Leitfadens für die BIM Modellierung in Revit’ (Guide to BIM Modelling in Revit) was developed closely with architecture, MEP, and structural engineering representatives. The goal is to provide users with valuable guidance to help improve their work and acquire more profound insights into modelling standards for BIM projects with Autodesk Revit. We contributed with our knowledge of the analytical model, MEP opening coordination and general modelling rules.

Authors: Alexander Hofbeck, Florian Gschwind

Publisher: Autodesk

The targeted use of parametrics and the automation of planning and checking processes allow us to break down interfaces and improve efficiency and collaboration. In the Autodesk University 2018 industry talk ‘Workflows – BIM als Paradigmenwechsel in der Tragwerksplanung’, Torsten Künzler and Alexander Hofbeck presented current solution approaches from Bollinger+Grohmann.

Our colleagues Diego Apellániz, Dajana Elez, Sebastian Dietrich, Nelli Gress and Ljuba Tascheva participated in the second AEC Hackathon in Germany, held July 20–22, 2018, in Berlin.

This event brought together professionals from the building industry to tackle everyday challenges through collaboration and the use of new technologies. Over the course of three exciting days, the B+G team, in cooperation with Goran Sibenik (TU Wien), developed an algorithm to clean up analytical models and optimise the interoperability workflow between Autodesk Revit and Dlubal Software RFEM. The hack was awarded the prize for ‘The Best Dynamo Project’!

We are joining the art-based research project ‘Fluid Bodies - Casting Without Formwork’ at the University of Applied Arts Vienna.

The research project challenges conventional formwork ideas and assumptions about bringing materials into form.

The project’s objective is to explore hidden potentials in the relationship between form, fabrication methods, and material behaviour ‒ and to test existing assumptions through cross-disciplinary efforts that merge architecture, sculpture, structural design, emerging fabrication technologies, and fashion design.

The expected result is a series of large-scale prototypic objects produced by various methods enriched from different disciplines.

The research is funded by the Austrian Science Fund FWF, and its ‘PEEK’ program.

For the Triennial EXTRA in 2018, the National Gallery of Victoria in Melbourne commissioned a large-scale, interactive installation designed by Studio Roland Snooks in collaboration with sound artist Philip Samartzis and Bollinger+Grohmann.

‘Floe’ is a speculative architectural sound installation tower made from seventy unique overlapping semitranslucent 3D-printed polymer panels resembling an iceberg in Antarctica.

The panels are attached to a filigree steel lattice with CNC-cut steel blades, machine folded to the exact angle and shape. The structural system of the steel lattice was optimised regarding the force flow within the structure, with steel thicknesses varying from 3 to 8 mm. Overlapping elements are connected via steel bolts to assemble bigger cross-sections.

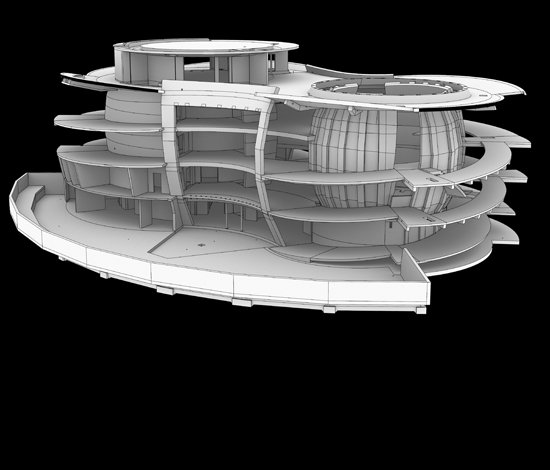

E-slab is a new type of concrete slab we have been advisors on and developed along with Snøhetta. The E-slab system incorporates ventilation, electricity, and sprinklers within the slab without needing a ceiling below the slab. This solution will save approximately 400–500 mm of ceiling height on each floor compared to a traditional hollow core slab, i.e.

In addition, the prefabrication process allows for a quick construction phase on site and facilitates design for disassembly.

The slab system is currently being incorporated into several ongoing projects.

This publication presents the computational design, optimisation, and realisation of a freeform object from high-performance concrete. It illustrates the design phase, the manufacturing and the so-called Möbiusbank itself. Moreover, two short papers give comprehensive explanations of the employed computational structural optimisation as well as a novel joining technique developed for the project.

Manfred Grohmann, Philipp Eisenbach, Moritz Rumpf: ‘Structural Surface – Computational design, optimisation and realisation of a freeform object from high performance concrete’, University of Kassel, Blurb Inc. San Francisco,

ISBN: 978-1-36-640026-0

PhD Dissertation of Philipp Eisenbach is about lightweight structures, and material-optimised systems are relevant in the building industry, particularly in the design of concrete structures.

This is not only for aesthetic reasons but also to use materials in a resource-conserving way. As one measure to reduce cross-section dimensions, increasing strength characteristics postulates the prefabrication of cementitious materials under laboratory conditions.

This thesis examines the contradiction between the possibility of realising slender concrete elements and the complexity of the discontinued homogeneity arising from necessary segmentations. Proposals of implementation strategies are demonstrated and verified based on selected case studies.

Philipp Eisenbach; ‘Processing of Slender Concrete Shells - Fabrication and Installation’; Kassel University Press,

ISBN: 978-3-7376-0258-7

In 2014, a student project was initiated at the University of Kassel to design and construct a slender concrete shell within 14 weeks. Under the guidance of architects and structural engineers, 27 students from the School of Architecture developed proposals for a shell structure to be prominently located on campus.

The project received sponsorship from DUCON®, providing the necessary high-performance concrete and mesh reinforcement. Following a competition phase, a concept for a Möbius strip-shaped concrete bench was selected as the winning design, and subsequent optimisation and construction phases were carried out.

Studio Roland Snooks was commissioned to develop the design for ‘The Future is Here’, a travelling exhibition organised by the Design Museum in London, with Melbourne as the first destination overseas. The design comprises two big tables and one small table with a cantilever fabricated from 3 mm glass fibre composite elements.

The project aimed to combine surface, structure, and ornament into intricate and irreducible assemblages. Glass fibre-composite material has the advantage of incorporating different materials to manipulate the structural behaviour of the final composite. Here the inlays or ‘beams’ of the composite are based on high-density foam placed according to an agent-based algorithm, defining the location and shape of the pattern.

Karamba3D was utilised to quickly exchange the different geometries and return structural information to the agents. The ’beams’ depth and width follow the logic of bending moments within the surface, which in turn gains its strength from the strategic placement of the beams and their dimensions accordingly. This strategy enables the surface to remain 3 mm thick while spanning and cantilevering considerable distances.

The project’s complexity was made possible by developing robotic fabrication techniques, including the extrusion of the fine-scale surface articulation.

‘Parapluie’, made of UHPC by Activating Membrane Effects, is an architectural concrete shell structure for a bus stop shelter designed for serial production through the reuse of the formwork. It is made of ultra-high-performance concrete, reinforced with a stapled micro mat reinforcement distributed over the whole cross-section with zero distance to the outer surfaces.

That material composition leads to a highly ductile behaviour substantiated by the biaxial homogenous cross-section layout that allows a linear elastic structural analysis.

The aim was to achieve a concrete shell that was as slender and lightweight as possible. A parametric form-finding process developed a system that can transfer shell loads primarily by membrane effects. The result is a concrete shell with no steel-embedded items and an edge thickness of less than 25 mm.

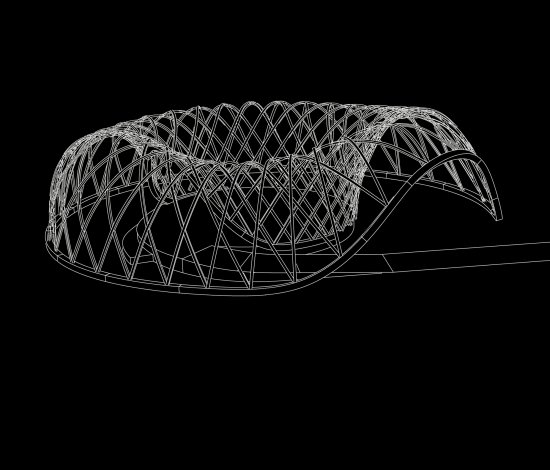

For the Sound Bites City exhibition at the RMIT Gallery, Jon Cherry and Nicholas Williams developed ‘The Torus’, a toroidal shape timber grid shell structure with a 21-channel loudspeaker system. Karamba3D was utilised as a design tool in the early design process, enabling a good workflow between the architects’ design platform and the engineers’ structural analysis tools.

Octopus is a multi-objective, evolutionary solver available for Rhino’s Grasshoppher3D. Robert Vierlinger developed the plug-in in close cooperation with Bollinger+Grohmann, and it is being used in our offices daily.

The genetic algorithm allows one to search for multiple goals at once and produces a range of optimised trade-off solutions between the extremes of each goal. It works similarly to David Rutten’s Galapagos but introduces the Pareto principle for evaluating multiple objectives within one optimisation process.

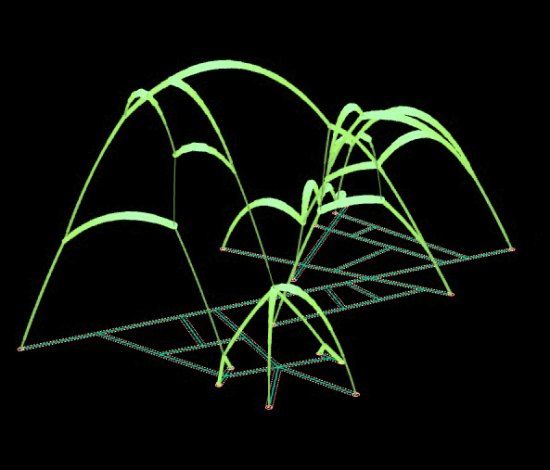

Klaus Bollinger, Clemens Preisinger, and Arne Hofmann were awarded the Austria ‘Baupreis’ in the category of Research and Development for the research project ‘Algorithmic Generation of Complex Space Frames’.

Karamba3D is a parametric structural engineering tool that accurately analyses spatial trusses, frames, and shells. The tool is fully embedded in the parametric design environment of Grasshopper3D, a plug-in for the 3D modelling tool Rhinoceros.

Clemens Preisinger is developing Karamba3D in close cooperation with Bollinger+Grohmann in Vienna.

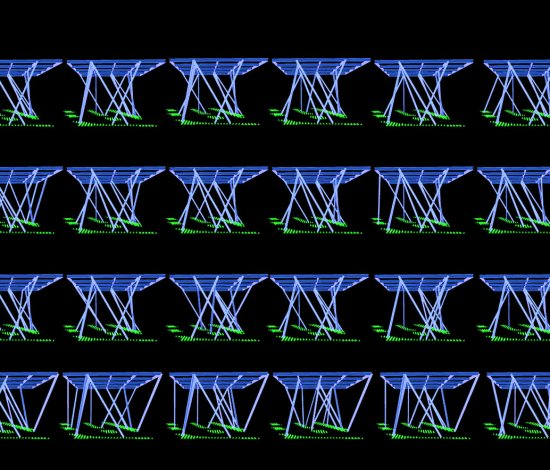

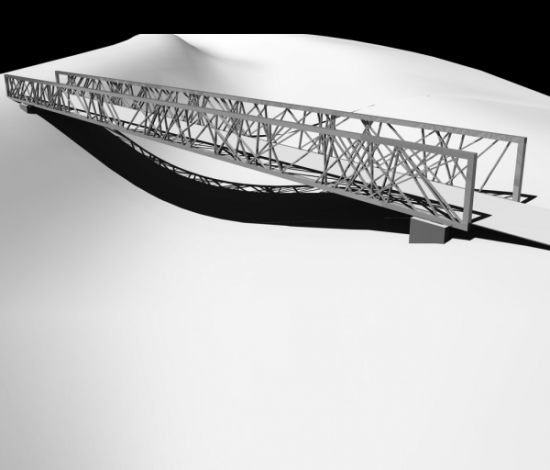

‘Brücke Reeden’ is a competition entry for a bridge design that utilised GENTs (Generic Exploration + Navigation Tool for Structural Design).

The bridge’s supporting structure takes the form of an irregular truss structure, which is generated through an optimisation algorithm to suit the unique requirements of the situation. The approach towards the structural design involves an agent system, where each truss element follows specific behavioural rules during the generation process. The behaviour of each element is influenced by the forces acting upon it and the deformation of the overall model.

The outcome is an irregular and effective structure, aligning perfectly with the architects’ vision.

Architects: FLOSUNDK (architektur+urbanistik)

The competition entry for 'Infobox' - an elevated overlook and info point for the Vienna Central Station construction site - was one of our early projects that employed an algorithmic approach to generate and optimise the column arrangement supporting the elevated building structure.

Although the box itself features a regular structural grid, the columns were designed to adapt to the irregular and disordered ground conditions and limited areas available for foundations.

Architect: Michael Wallraff

The research project ‘Algorithmic Generation of Complex Space Frames’ conducted at the University of Applied Arts Vienna led to the development of the unique tool GENTs. This tool creates diverse framework structures and goes beyond mere structural optimisation. GENTs integrate state-of-the-art optimisation algorithms with powerful multiprocessor static software to enable the generation of complex spatial structural systems.

‘Algorithmic Generation of Complex Space Frames’ is a research project conducted at the University of Applied Arts at the Institut for Structural Design.

This research investigates the algorithmic generation of complex space frames and their relevance in structural engineering and architectural design. Contemporary structural design prioritises regularity and effectiveness, but there is a growing interest and demand for irregular and free-form designs. Existing design methods must be improved in developing optimised irregular structures, creating a gap between architectural requirements and available tools. Complex, non-regular structures have inherent load-bearing capacities, requiring a holistic approach. Modern technology enables efficient analysis of alternative solutions, generating systems with emergent load-bearing capabilities. The research explores innovative approaches for developing effective irregular forms while integrating practical construction principles.